A bent crankshaft in a diesel generator can lead to catastrophic engine failure, excessive vibrations, and costly downtime. Addressing this issue promptly is crucial to restoring performance and preventing long-term damage. we’ll explore why crankshafts bend, step-by-step correction methods, and tips to avoid recurrence.

Why Do Diesel Generator Crankshafts Bend?

Crankshafts are robust but not immune to deformation under extreme conditions. Common causes include:

Overloading: Exceeding the generator’s power capacity strains the crankshaft.

Hydrolock: Liquid (coolant or fuel) entering the cylinder, causing sudden resistance.

Improper Handling: Dropping the crankshaft during maintenance or transport.

Poor Lubrication: Insufficient oil causes friction, overheating, and warping.

Fatigue: Long-term stress from imbalanced loads or misalignment.

Signs of a Bent Crankshaft

Excessive Vibration: Unusual shaking at idle or under load.

Knocking Noises: Metallic clanking from the engine block.

Oil Leaks: Damaged seals due to misalignment.

Difficulty Starting: Irregular rotation prevents smooth ignition.

Methods to Straighten a Bent Crankshaft

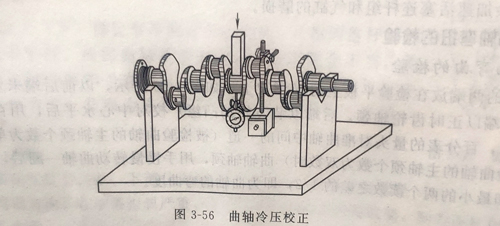

1. Cold Straightening (Hydraulic Press)

Process:

Secure the crankshaft in a hydraulic press, aligning the bent section.

Apply gradual pressure to the apex of the bend.

Recheck runout after each adjustment until within tolerance.

Pros: Suitable for minor bends (<0.1 mm/m).

Cons: Risk of cracking if over-pressurized.

2. Heat Straightening

Process:

Heat the concave side of the bend to 500–600°C using an oxy-acetylene torch.

Allow controlled cooling; contraction pulls the metal back into alignment.

Pros: Effective for cast iron crankshafts.

Cons: Requires expertise to avoid weakening the metal.

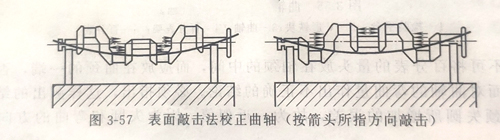

3. Peening Method

Process:

Use a rounded hammer to strike the convex side of the bend, stretching the metal.

Repeat until the crankshaft straightens.

Pros: Low-cost for small bends.

Cons: Labor-intensive and less precise.

Post-Straightening Steps

Polishing: Smooth journals and bearings to remove surface imperfections.

Magnetic Particle Inspection (MPI): Detect hidden cracks or stress fractures.

Dynamic Balancing: Test on a balancing machine to ensure smooth rotation.

FAQs About Crankshaft Straightening

Q: Can I straighten a crankshaft without removing it?

A: No. Accurate measurement and alignment require full access to the crankshaft.

Q: How long does the process take?

A: 4–8 hours for minor bends, plus disassembly/reassembly time.

Q: Is a straightened crankshaft reliable?

A: Yes, if done correctly. However, repeated bending reduces its lifespan.

Final Thoughts

A bent crankshaft is a serious but solvable issue for diesel generators. While minor bends can be corrected with care, severe cases often warrant replacement. Regular maintenance and load management are key to preventing this problem. Bookmark this guide to act swiftly if your generator shows signs of crankshaft trouble!

More information: http://www.huaquan168.com/