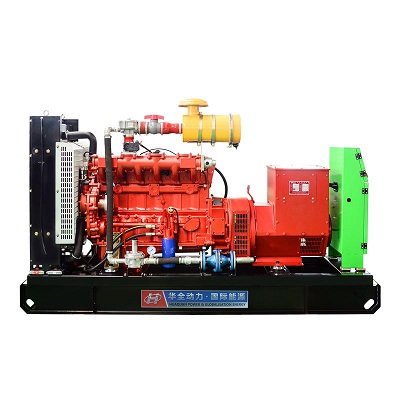

Gas generator sets are new power generation equipment developed to meet the world's environmental protection requirements and the new market environment. It has the advantages of a wide output power range, high reliability in starting and running, good power generation quality, light weight, small size, simple maintenance, and low low-frequency noise.

1. Softened water must be used for cooling water of the unit.

2. The machine room should be spacious and bright, and a ventilation fan should be installed to ensure good ventilation.

3. During installation, the chassis and the foundation should be leveled with flat pads. The contact area should be more than 60% and evenly distributed.

4. The machine room should be away from open flame areas.

5. The gas must be desulfurized, dehydrated, and dusted, with a flow rate of ≤0.25Nm3 and hydrogen ≤10%.

6. Indoor lighting, switches, lines and electrical appliances should adopt explosion-proof measures and be firmly fixed.

7. The machine room should meet fire protection requirements and be equipped with fire extinguishers and other fire-fighting equipment.

8. Install a combustible gas alarm device in the machine room to detect combustible gas leaks in time.

9. The inner diameter of the external main pipeline of the gas pipeline of a single gas engine below 60kw should

be no less than 2 inches, and the inner diameter of the part close to the engine should be no less than 1 inch! Above 60kw, the inner diameters are 3 inches and 2 inches respectively. And gas valves (stainless steel ball valves), drain valves, and anti-backfire devices must be installed. After the gas pipeline is welded, the welding slag should be cleaned (with high-pressure air).

During use, the above operating procedures must be strictly followed to ensure the normal operation of the gas generator set.